Race Cars

$ 23,900

1968 MGB GT Track Car (Street Legal)

Description:

Rover Aluminum V8 Powered 1968 MGB-GT

as published in British V8 Newsletter, Volume XV Issue 3, December 2007

State: Connecticut

Model: 1968 MGB-GT

Engine: Rover aluminum V8 (5.0L)

Conversion by: owner

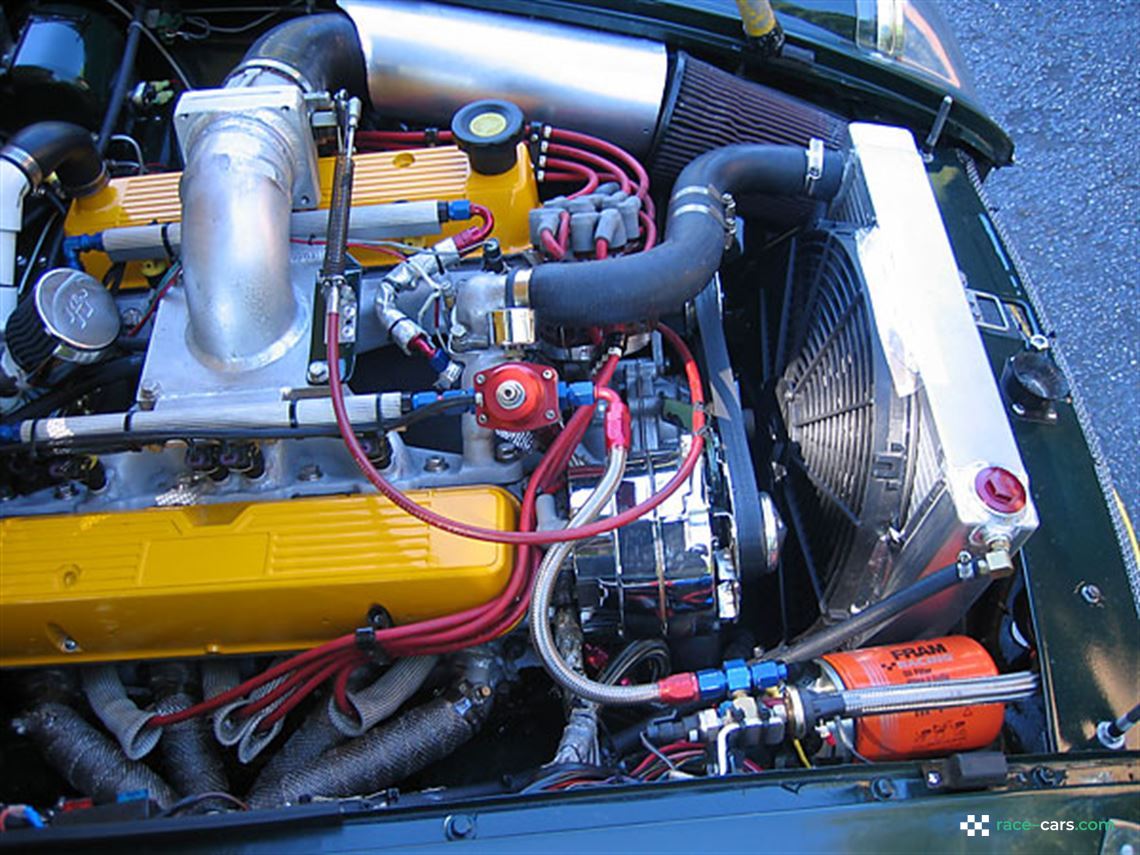

Engine:4.6L Rover motor (with cross-bolted main bearings, etc.). The engine has been built up to 5.0L (i.e. stroked via offset crankshaft grinding), balanced, and blue-printed. It has roller rockers and a new roller cam (108 degress lobe separation, 258/265 duration at 0.585" lift, which replaces a previous cam with 110 degrees lobe separation, 240-244 duration at 0.050" lift), oversized valves, ported Buick 300 aluminum heads, and JE pistons. MSD ignition and Simple Digital Systems EFI management system.

Induction: Fuel injected with 40 lb. injectors, open plenum with a 75mm throttle body fed through a K&N Filter; a water injection system is next on the list.

Oil System: The geroter oil pump is inside the Rover front cover, but the front cover was modified so the oil relief valve and a remote filter could be mounted on the fender well. You can thus easily adjust the oil pressure to whatever you want it to be. It's currently adjusted to provide 30lbs at idle, 50 while cruising, and 75 when you get on it. This installation also provided clearance for the stock MGB steering rack.

Cooling: C&R 3" core double pass aluminum radiator; Spal 16" puller and a 12" pusher with a fan controller unit. Coolant is glycol. 25 row oil cooler mounted under the deck. Undersized pump pulley.

Exhaust: 1 5/8" thru-fender headers into a dual 2.5" exhaust system with an X-pipe under the transmission. (See photo.) The high performance mufflers are mounted vertically on either side of the fuel cell.

Transmission: WC T-5 with a cruising 5th - great fuel economy on the highway and it's dependable handling the power. The bell housing was machined to ensure proper run-out. Tilton hydraulic throwout bearing (slave cylinder) with a Center Force Clutch. Custom fabricated driveshaft by D&D Fabrication.

Rear Axle: Dana 44 from a Jeep or mail truck, with 3.73:1 gears and a limited slip differential. (Bought from D&D Fabrication.) It fit nicely under the body kit!

Front Susp.: Uprated lever arm shocks with comp valves and 20 weight oil; 2" lower racing springs with longer lower arms all sitting on nylatron bushings. 1" custom sway bar with fully adjustable end links making it capable of setting pre-load.

Rear Susp.: Koni shocks on 2" lowered racing springs; 5/8" sway bar; anti-tramp bars and track bars.

Brakes: 12" vented front rotors and 12" solid rotors in back. Wilwood 4-pot calipers on all 4 corners with a Tilton dual master, remote reservoirs and a rear brake proportioning valve.

Wheels/Tires: The street tires are 16x8's with Pirelli 225's in the front and 255's in the rear. For competition, the tires are 17x8's "DOT" slicks (225's in the front and 255's in the rear.)

Weight: 2,089 with a half tank; weighed some five years ago and much has changed on the car: glass, window cranks and all unnecessary weight has been removed.

Electrical: Mix of MG and new wiring necessary to support the EFI, fuel pumps and electronics. 160 amp alternator. Gauges are Autometer comp. No audio! (Weighs too much.) The battery is installed in the LH battery box.

Chassis Mods: The car was stripped and etched before the Sebring body kit with a fiberglass hood was installed. A six point roll cage was also installed however I never liked the installation. The forward track bar mount also acts as a safety catch for the driveshaft. The car has a 14 gallon fuel cell and a 4 gallon surge tank (in the RH battery box) so the EFI system won't ever run dry under cornering. I installed an aluminum deck in the back to add an additional fire barrier between me and the fuel cell.

Interior: The interior was stripped and painted lightweight door panels were fitted. The dash is original, except stripped of its padding and modified to take the 2 5/8 inch gauges. There's no insulation and the MG rubber floor mats and carpet all slide right out. A friend had a Momo carbon fiber chair and competition wheel and belts which he gave me! The side glass was removed and the window crank assemblies were also stored.

Fuel enters the fuel rail by the #1 cylinder injector (i.e. shown here on the throttle-body side) and circulates around to where the pressure regulator is positioned. Excess fuel runs back to a surge tank in the passenger-side battery box. All fuel lines are -8 (3/8") except for the EFI pump's gravity feed from the bottom of the surge tank to the inlet port on the pump, which is -10 (1/2") line to prevent pump starvation.

I've been running 30 lb injectors, but they're getting replaced with 40 or 50 lb injectors this winter.

The braided hose on the forward side of the regulator goes to a bleed cap (for removing air from the system) and to the fuel pressure sender and fuel pressure cut off switch. (These components are mounted high on the passenger side inner fender.) The SDS EFI CPU can be ordered with a fuel-pressure cutoff switch to stop fuel flow in the event of an accident. The relay works by monitoring both fuel pressure and engine RPM.

C&R (Visteon) aluminum radiator, viewed from front and back respectively, with electric fans. The Spal fan electronic fan control unit is mounted inside the car (by the passenger's left knee).

The dash is the original part (1968 MGB "Abingdon pillow"), except with all the padding stripped off, holes welded closed, new larger holes punched where the gauges sit currently, and recovered in vinyl.

The switch panel in the center console is just a piece of sheet aluminum with holes punched for the switches. I isolated everything electrically. There are 4 fuse panels in the car; two under the hood replacing the MG unit and two tucked up under the dash adjacent to the battery cutoff switch.

The toggle switches control the ignition, EFI CPU, fuel pump, surge (fuel) pump, Spal electric cooling fans and controller, headlights, hazard lights, driving lights, and windshield wiper. The horn, running lights, head lights and wipers are still wired through the MG wiring harness which I took out, inspected, cleaned and reinstalled. The high beam and turn signal indicators were relocated to the center switch panel. The on/off dash light switch was also retained as was the center console map light. I kept the cigar lighter to power internal lights and radar detectors, phone chargers, etc.

All front-to-back wiring (e.g. the running lights circuit) runs along the inside of the passenger side floor. The fuel lines are run under the passenger side floor and it seemed to made sense to separate them in case of an accident. The carpet and floor mats slide right out, making it easy to remove weight when heading off to the track.

The steering wheel is a quick-release Momo unit. The steering shaft and linkage were shortened and re-routed. The car has speedometer, tachometer, oil pressure, fuel pressure, brake pressure, water temperature, oil temperature, and volt meter gauges installed. The yellow light tells the driver when to shift, and the red light alerts him if oil pressure drops. There are also mechanical oil pressure and fuel pressure gauges under the hood for obvious reasons.

The SDS electronic fuel injection control box is pretty easy to use. (You can see the control unit to the right and below the steering column.) The system includes a tach pickup, water temperature sensor, air temperature sensor, MAP (manifold absolute pressure) sensor, and throttle position sensor. (There's also a cold start solenoid if you want to hook it up.) It sounds complex, but it isn't. I have had lots of mechanical motor issues but never once has the EFI caused a problem.

The gas pedal is floor mounted, and the throttle is actuated by a heavy duty cable with locking retaining spring clips.

The bottom righthand photo shows the EFI high-pressure fuel pump control unit, which is mounted behind the passenger seat. This unit monitors and controls the fuel pump duty based on engine RPM.

These photos show the battery boxes, as viewed from the rear of the car. The LH (driver's side) box houses the battery and a low pressure fuel filter. Instead of running battery cables under the floorboard, the main battery cable runs through the battery cover via a bulkhead fitting.

The RH (passenger's side) battery box houses a custom, fabricated aluminum fuel surge tank. A low-pressure, high-volume pump transfers fuel from the fuel cell into this tank. A high-pressure, high-volume pump takes fuel from the bottom of the surge tank to a filter and then up to the engine. The fuel moves around the engine's fuel rails and to the pressure regulator. Excess fuel is released by the pressure regulator, and travels back to the surge tank.

The fuel cell has 3 lines: pick-up, return, and also a vent line back from the surge tank to the fuel cell. It's complex for sure, but it is bullet-proof!

In this particular installation, the EFI system's electronic controller spins the high-pressure pump at 50 percent capacity until the engine reaches 3,000 RPMs, and then it pumps at full output.

Website:

http://www.britishv8.org/MG/LorenzHassenstein.htmDetails:

| Seller: |

Race-Cars.com Joined January 2009 |

|---|---|

|

Mike Walters Seller's other listings |

|

| Company: | Race-Cars.com |

| Country: | United States of America |

| City: | Race-Cars.com |

| Phone: |

+1 737 241 3999 +1 737 241 3999 |

| Condition | Used |

| Trade or Private: | Private |

| Currency: | |

| Price: |

$23,900

Make an Offer |

| Added: | 07/20/2022 |

| Views: | 16326 |

|

Share by Email Print page Report Sold |

|